Our Solution to your warning

Engine Management Sensors

Engine Management Sensors come in various forms and are part of the self-regulating systems of modern engines. Some Engine management sensor information is responded to within the engine and we may know little about it whilst other sensor information is relayed to us via lights on our dashboard, such as if water temperature is too high or oil or fuel levels too low. J&S offers high quality engine management sensors for any car. They are vital to the continued running of your vehicle. Sensors can be prone to faults, so it is important to check that your engine management sensor is operational on a regular basis.

Ignition Coils

Within an automobile's ignition system, an ignition coil plays an essential role in transforming the battery's 12 volts to the 20 or 30 thousand volts or more needed to spark the spark plugs.

Lambda Sensors

The Lambda sensor or oxygen sensor is located in the manifold or exhaust system. They analyse the amount of oxygen in the fuel being used by your car. The Lambda sensor is a vital component of any modern car, as it makes modern fuel injection possible and helps to regulate the emission of harmful gases into the atmosphere. This sensor then sends signals back to the ECU to calculate the engines fuelling requirements. There are quality Lambda sensors for every make and model of modern car and they are usually located in the exhaust stream. It is worth checking that your Lambda sensor is working properly, as faulty ones can lead to the catalytic converter becoming damaged and result in expensive repairs.

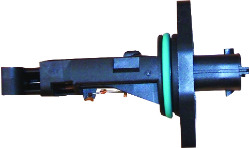

Air Mass Meter

An instrument which measures both engine intake air mass and factors which affect air density, such as temperature, humidity, and pressure.

Glow Plugs

A glow plug looks similar to a spark plug. Instead of spark plugs, glow plugs are used to heat and start diesel engines. It takes only two or three seconds for glow plugs, once activated, to generate sufficient heat to warm the engine block so that it's safe to start the vehicle. Glow plugs get it going when the engine is cold or ambient temperatures are low. At J&S we stock and supply quality glow plugs for any car.

Crankshaft Sensor

A crank position sensor is an electronic device used in an internal

combustion engine to monitor the position or rotational speed of the crankshaft. This information is used by engine management systems to control ignition system timing and other engine parameters. Before electronic crank sensors were available, the distributor would have to be manually adjusted to a timing mark on the engine.

The crank sensor can be used in combination with a similar camshaft position sensor to monitor the relationship between the pistons and valves in the engine, which is particularly important in engines with variable valve timing. This method is also used to "synchronise" a four stroke engine upon starting, allowing the management system to know when to inject the fuel. It is also commonly used as the primary source for the measurement of engine speed in revolutions per minute.

Common mounting locations include the main crank pulley, the flywheel, the camshaft or on the crankshaft itself. This sensor is the most important sensor in modern day engines. When it fails, there is a chance the engine will not start, or cut out while running.

Map Sensor

The manifold absolute pressure sensor (MAP sensor) is one of the sensors used in an internal combustion engine's electronic control system. Engines that use a MAP sensor are typically fuel injected. The manifold absolute pressure sensor provides instantaneous manifold pressure information to the engine's electronic control unit (ECU). The data is used to calculate air density and determine the engine's air mass flow rate, which in turn determines the required fuel metering for optimum combustion (see stoichiometry) and influence the advance or retard of ignition timing. A fuel-injected engine may alternately use a mass airflow sensor (MAF sensor) to detect the intake airflow. A typical configuration employs one or the other, but seldom both. MAP sensor data can be converted to air mass data using the speed-density method. Engine speed (RPM) and air temperature are also necessary to complete the speed-density calculation. The MAP sensor can also be used in OBD II (on-board diagnostics) applications to test the EGR (exhaust gas recirculation) valve for functionality, an application typical in OBD II equipped General Motors engines.

Oil Pressure Switch

Problems with engine management switches are comparatively rare and may require diagnosis by a qualified mechanic. If any part of your car engine management system appears not to be working then the problem may lie with one of the engine management switches.

Replacement engine management switch are available from one of our Motor factors take a look for your nearest Motor Factor on our

Map - Factor Finder. If you are unsure about the replacement engine management switches, call us for expert advice - 01 629 7999

EGR Valve

The EGR valve consists of a poppet valve and a vacuum diaphragm. When vacuum is applied to the EGR valve diaphragm, it pulls the valve open allowing exhaust to pass from the exhaust manifold into the intake manifold. Some engines have "positive back pressure" EGR valves, while others have "negative backpressure" EGR valves. Both types contain a second diaphragm that modulates the action of the valve. This prevents the valve from opening unless there is a certain level of exhaust backpressure in the system. EGR valves are calibrated for specific engine applications. The wrong valve may flow too much or not enough exhaust and cause emission, drive ability and detonation problems.

EGR valves do not normally require maintenance or replacement for preventative maintenance. But the valve can become clogged with carbon deposits that cause it to stick or prevent it from closing properly. Dirty EGR valves can sometimes be cleaned, but replacement is necessary if the valve is defective.